I use KiCAD (or anything else that can output Gerber files) to design my boards and FlatCAM (or GCAM SE, although this one has some notable limitations) to generate the G-code then, since my 3020 mill is driven via an Arduino-based GRBL box, I execute that G-code with any suitable GRBL GUI, such as Universal GCode Sender, GrblControl or bCNC - the latter two even offer built-in PCB auto-levelling although I tend to just use a pre-milled flat piece of HDF.

As I mentioned, I'm very new, entirely self-taught so far and completely inexperienced so please assume I know pretty much nothing at all, as that's not far from the situation. I only have a 12000 rpm spindle which puts out about 11800 so please also consider this in any suggestions - And all comments and thoughts welcome. I did have a good bit that came with the router, and it worked well at first, but not for long and the other bits I had which all looked the same were no good at all. Cutting depth isn't perfect, so I'm hesitant to use wider bits. Interestingly, there is clearly need for a PCB layout application with milling intended from the start, but I couldn't find one at all - even among the commercial packages.Īnd are there any better bits out there? That cans still give me sub 10-thou cuts? I can live with 14-thou if necessary, but 15 too much and it needs to be reliable.

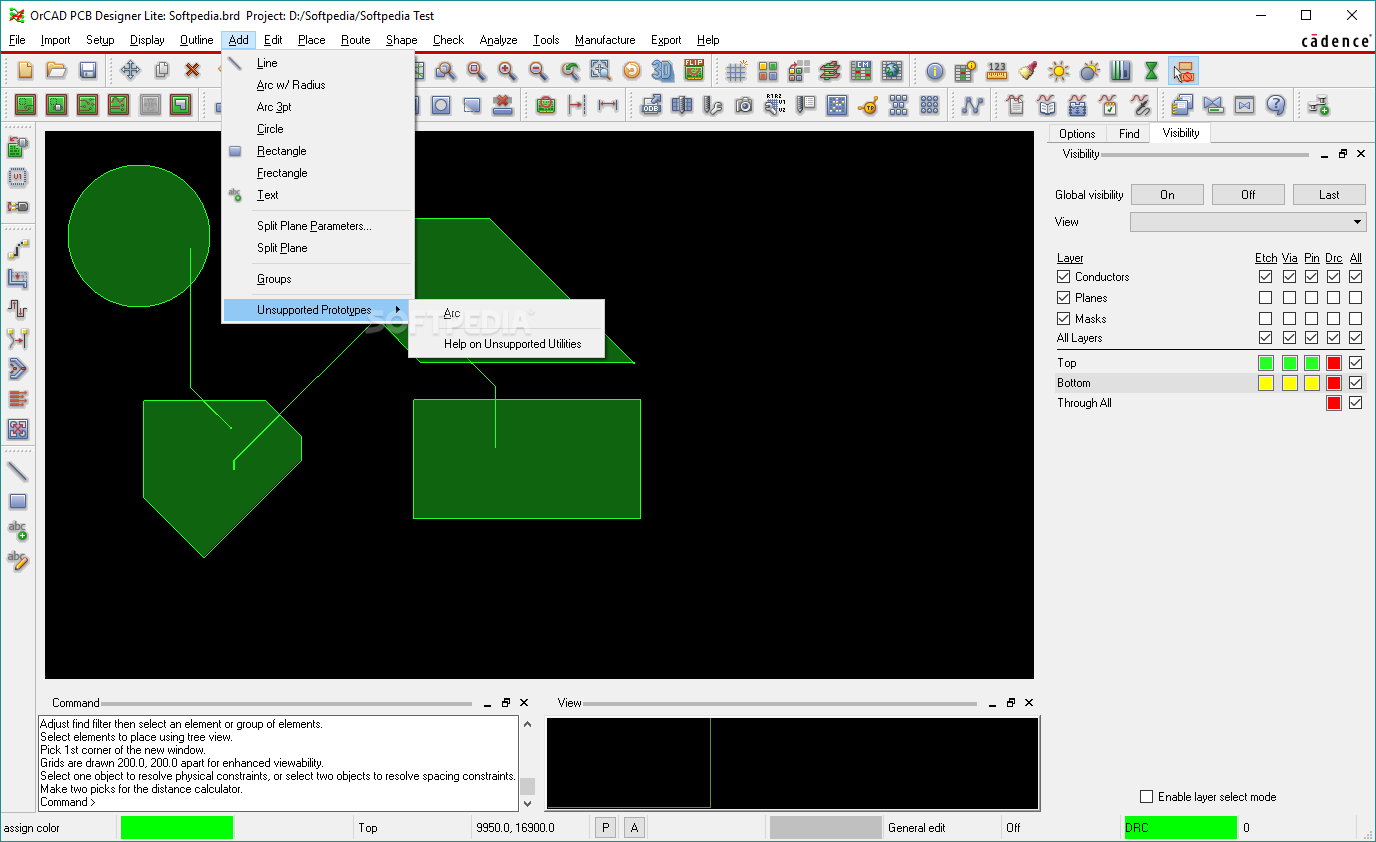

#Diptrace vs eagle eevblog software

Is there are other free software packages I should be looking at that others have tried and can recommend? It's all working, but it could work better. At best, I get around this by manually editing the gcode.Īnyway, this brings the newbie question. One example is a simple way of cutting the PCB since I can't edit the gcode ( and haven't worked out if FlatCAM can edit it ) and flatcam treats the outline as a path and tries to mill both sides which is a problem. I'm using 0.1mm 10degree engraving bits, which make a mess, but it's easily cleaned up with a quick polish after engraving, and I'm getting sub 10-thou cuts with a new bit and even worn bits seem OK.Ĭurrently, I'm missing some easy options. This also works remarkably well, and puts out Mach3 format gcode. This is surprisingly good, is free to use. It's the only free PCB software I've been able to find that outputs Gerber.

So after looking around and trying different things, I put together a basic setup involving But it's been challenging even finding free software to cover every part of the process.

#Diptrace vs eagle eevblog windows

I had a 6040 mill gathering dust in the shed ( had problems with the parallel port and shelved it for a decade ) so I pulled it out, fixed it up and added a USB breakout to work with Windows 10. I used to make PCBs with photoresist and a double sided UV case, but for the times I make PCBs, it's a pain to mix chemicals up in the required quantities for a single PCB and then dispose of it all. This means avoiding commercial software where possible, or anything that's tied to a specific PCB manufacturer.

So I'm trying to do things as cheaply as possible until I get the hang of it. And by new, I mean I had never even powered up a mill or milled anythingbefore three weeks ago and I'm still only self-taught. My first post here, and I'm new to both CNC and milling PCBs.

0 kommentar(er)

0 kommentar(er)